LR-Series

- TOP

- products Info

- LR-Series

LR-SeriesLR-Series

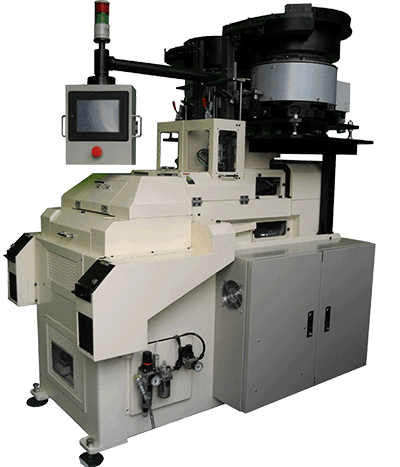

The nut tapping machine specialized for fabrication of long works such as high nuts, color nuts, etc., that cannot be fabricated with a bent shank nut tap, as well as large diameter / thin type hexagon nuts.

The designated straight tap is used. By adding the process to take out the completed nut from the tap for each screw cutting, the continuous automatic fabrication process became possible without switching normal / reverse operation.

Because an independent motor is mounted on each shaft, independent operation on the respective shafts is possible.

The screw cutting failure detection mechanism using sequencer control is mounted as the standard. The operation similar to that of the NA series is possible on the touch panel.

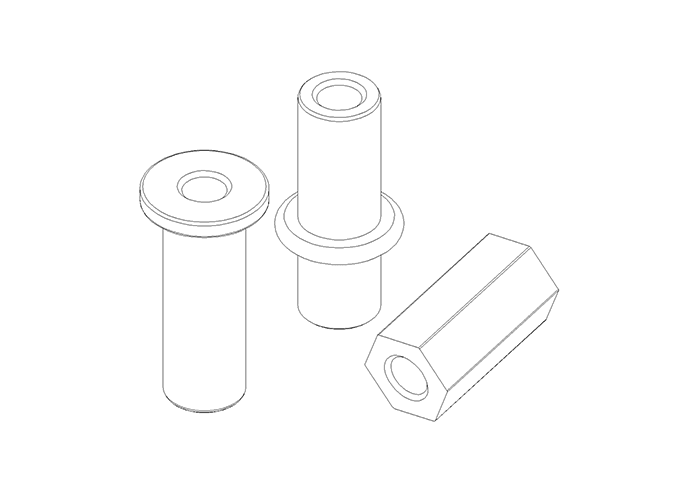

Select by shape of nut

LR nut

LR-Series

| Range of screw processing | |

|---|---|

| LR-120 (150) | M8~M20 |

| LR-120CB | M12~M45 |

| LR-30 | M4~M8 |

LR-Series

LR-Series

| Model | LR-120 (150) | LR-120CB | LR-30 |

|---|---|---|---|

| Range of screw processing | M8 ~ M20

Nut L size 105mm (125mm) |

M12 ~ M45

But, thick diameter screws:P0.5 to 1.0 |

M4 ~ M8

Nut L size 30mm |

| Nut tapping style | Biaxial slide air system Spring pushing type |

||

| Work fixing method | Lever type hydraulic chuck guide | CB type clamp guide | Hydraulic chuck guide or CB type clamp guide |

| Shape of tap used

(Straight tap) |

L450mm (L580mm) | L350mm | L210mm |

| Tap replacement style | Lift-up type

(Mouthpiece weight open / close) |

Lift-up type

(Mouthpiece weight open / close) |

|

| Work feeding style | Parts feeder or dedicated conveyer | Parts feeder | |

| Stroke setting for main shaft rotation & screw thread cutting | Preset type (the number of threads setting)

Digital panel meter or touch panel |

||

| Main shaft motor spec. | Induction motor x2

2.2 or 3.7kW (3 phase / 4P) |

Induction motor or Gear motor x2

3.7 or 5.5kW (3 phase / 4P) |

Induction motor x2

0.75 or 1.5kW (3 phase / 4P) |

| Main shaft rotation range | 500~1500rpm

(2.2kW motor) 300~1000rpm (3.7kW motor) |

500~1500rpm

(Induction motor)150~600rpm (Gear motor) |

950~2500rpm |

| Main shaft control method | Inverter | ||

| Coolant pump

(Dip type coolant pump) |

400W (3 phase/2P) | 250W (3 phase/2P) | |

| Hopper driving motor | * | ||

| Chip separator | Induction motor 25W

(3 phase/4P) |

||

| Hydraulic unit | 1.5 KW (3 phase/4P)

Max. using pressure 3.5 Mpa 3.5MPa |

0.75 KW (3 phase/4P)

Max. using pressure 3.5 Mpa 3.5MPa |

|

| Control device | Sequencer / Touch panel | ||

| Production counter | Touch panel

(Tap lifetime / total count) |

||

| Failure detection items | Chamfer failure / clogging / empty / doubling / reamer torque | ||

| Other remarks | Max. shaft diameter: 30 mm Max. flange diameter: 50 mm |

Max. shaft diameter: 30 mm Max. flange diameter: 50 mm |

Max. flange diameter: 30 mm Max. shaft diameter: 20 mm |

| Main replacing parts | Hydraulic chuck / mouthpiece / weight contact board / tap holder / chip guard | Chute / chuck fixing board / nut fastening clamp / mouthpiece / weight contact board / tap holder / chip guard | Chute / hydraulic chuck / mouthpiece / nut sending pin / tap holder / chip guard |

| Cutting lubricant tank capacity | 160L (180L) | 160L | 110L |

| Machine size | 1230mm×1600mm

×H1900mm (1230mm×1860mm ×H1900mm) |

1230mm×1600mm

×H1900mm |

920mm×1520mm

×H1700mm |

| Machine weight | 1650kgs (1750kgs) | 1650kgs | 1000kgs |

| Other standard functions | * | ||

| Options / others | * | ||

| Production volume per minute (for reference) | 4 to 12 piece / One axis | 2 to 6 piece / One axis | 4 to 10 piece / One axis |

Please do not hesitate to contact us

if you have any questions about products.

-

HeadTel.03-3743-5321 / Fax.03-3744-5253

20-16 Higashi-kojiya 1-chome,

Ota City, Tokyo 144-0033 Japan